External Wall Insulation (EWI)

WHAT IS …

External Wall Insulation (EWI)

External wall insulation (EWI) is a type of insulation that goes on the outside of the walls of your house. Insulation boards are fixed to the outside of your house and then a lovely new coat of weatherproof render is applied to freshen up the exterior of your home in your choice of colour.

This insulation is just like wrapping your home in a blanket! It is a high performance insulation, very effective at warming up the interior of the home and reducing energy bills.

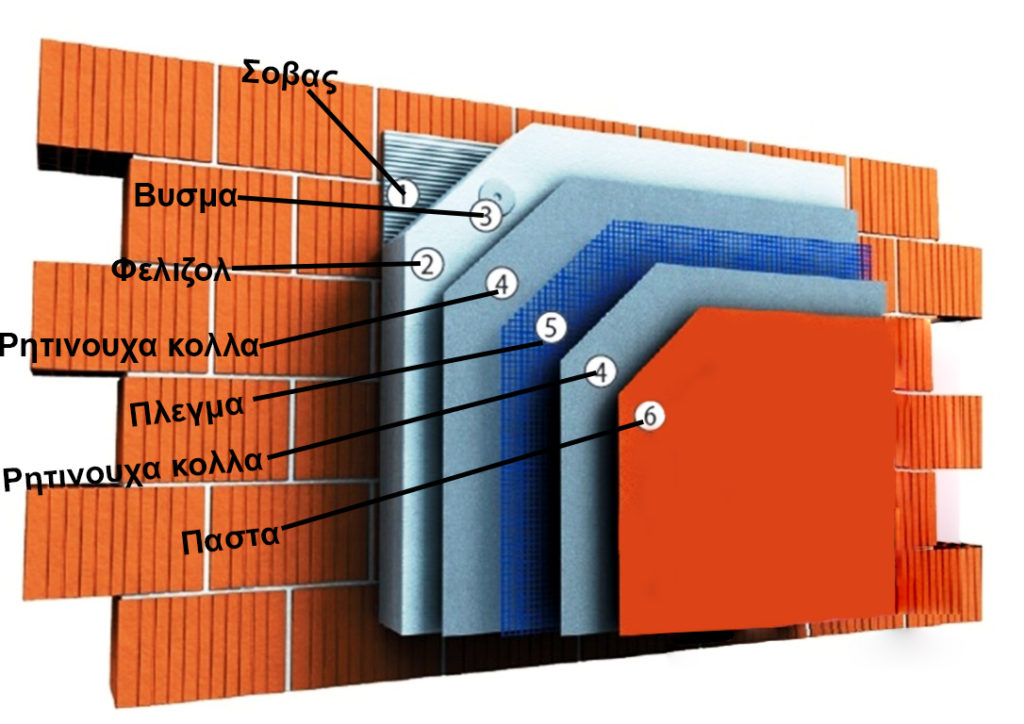

You can use insulation boards (either EPS, mineral wool, or PIR) which are agrément certified and achieve a U-value of 0.27W/m²K or lower, compliant with SEAI standards. These are fixed to the wall using an adhesive coat, and the boards are then covered with a reinforcing mesh for strength and longevity and secured to the wall using mechanical fixings. The final layer is weather proofing render, which protects your insulation over time and gives a pleasing finish to the walls in a colour of your choice.

"External thermal insulation is a valuable tool for energy saving and aesthetic upgrading of buildings, which quickly recovers the cost of its application."

- External wall insulation critically reduces heat loss.

- Increases the market value of the property.

- It improves thermal performance of buildings, resulting in reduced heat loss and lower energy bills.

- It helps to regulate indoor temperatures, making homes more comfortable in both summer and winter.

- This type of insulation does not reduce internal floor area.

- It can enhance the appearance of buildings.

- It is the most rational solution for existing buildings that are not insulated or poorly insulated.

- Acoustic Insulation and Fire Resistance.

How to install external wall insulation

Here are the step you need to follow when installing external wall insulation.

The first step before beginning the external wall insulation installation process is to carry out a render test. This will identify whether the existing render is strong enough to support the insulation. If the render is strong enough, it can simply be smoothed so that the insulation can be applied directly onto it. If the render is not strong enough, all existing render will need to be removed prior to the installation of insulation.

Once the render has been tested and smoothed down or removed as appropriate, all pipework must be removed from the building before the installation process can begin. Temporary downpipes must also be installed to prevent water from running down the side of the building, and any waste pipes or soil pipes should either be removed or extended away from the walls – this would allow the building to function as normal during the installation process.

External wall insulation does not normally reach the ground but instead begins a few inches or feet above. Once you’ve decided on the height, this is where the aluminium start track, or carrier tray, will be installed. This creates a level starting point and can also be used to fit beading.

Once the starter track has been installed, the application of the insulation boards onto the wall can begin. A layer of adhesive is applied to each board, and then they are stuck onto the wall in a staggered pattern. When windows and other obstructions are reached, the insulation boards are cut to fit around them.

Once the insulation boards have been installed, a rasp is used to file off the edges of the boards where required, in order to ensure the surface is completely flat.

As well as the adhesive, mechanical fixings are also used to secure the insulation boards. Around 10 fixings are hammered in per square metre, to ensure the insulation boards will not get blown off or fall off during periods of bad weather.

Corner beads and stop beads are a great way to ensure the insulation remains secure and tight around windows, doors and other obstructions, creating neat and tight edges and preventing the insulation from touching other materials.

Once the boards and beading have all been installed, two layers of render with strengthening properties are applied, with a fibreglass mesh sitting between the two layers of render.

Once the strengthening render and reinforcing mesh have been installed, a primer is painted on. This primer often contains granules which help the final render coat to stick, and the primer tends to be colour matched to the final render, in order to ensure no colours show through.

The final coat of render can now be applied. This render is the last coating in the installation process, meaning that it is important to choose the exact colour and texture you like, as it will be in view on the outside of the building.

WHICH ARE...

The Benefits of External Wall Insulation (EWI)

Improves energy efficiency and reduces energy bills

By ensuring that heat remains within your property, energy bills are dramatically reduced.

Minimises Thermal Bridging

Thermal bridging occurs when there are gaps within an insulation system. These gaps are where heat loss is significantly higher, becoming concentrated to this area and allowing water and condensation to gather. Thermal bridging can significantly reduce the effectiveness of insulation, however with EWI thermal bridging is minimised due to the fact that the system is external and is completely seamless; there is no need for breaks within the insulation boards.

Reduce Damp and Condensation

Insulation slows the rate of heat transfer by retaining the heat within the walls; condensation occurs when hot air comes into contact with cold walls. Because the external walls of the property are warmer with EWI, condensation is vastly reduced, therefore helping improve indoor air quality and maintain structural integrity.

Improves Thermal Comfort

Thermal comfort means that a property is kept at a comfortable temperature throughout all weather conditions. Whatever the weather, one of the benefits of EWI is that it can ensure that the inside of your property is the perfect temperature for feeling comfortable.

Increase Lifespan of Building Fabric

EWI covers the entirety of the exterior of a property, wrapping it in a thermal blanket that not only prevents heat loss but also protects the building fabric against weathering. The external render that finishes the system benefits the property by acting as a weather-proof barrier, preventing water ingress and damage from extremes of weather.

Improves Aesthetics, Renovates and Protects your Building

Part of an EWI installation includes a render finish on top of the insulation boards to ensure the system is watertight. This is not only highly functional but also incredibly aesthetically appealing. EWI Pro renders come in a wide range of colours and textures for a unique and customisable finish that will stand the test of time.

Save Floor Space

It takes up no internal floor space; the entirety of the building is cocooned in insulation which is secured to the external walls with adhesive and mechanical fixings.

Protects the environment

Your carbon footprint is dramatically reduced with external wall insulation because you use less gas and electric heating throughout the year due to your high levels of insulation, therefore households with EWI benefit from the fact that they are contributing towards helping the environment.

Mix and Match

For some houses you’ll find a combination of external and internal wall insulation is either necessary or practical. You may have to use internal insulation on the front to maintain the façade and therefore satisfy planning restrictions. However, the house could still have external insulation across all other walls.

Another example is if a pathway or driveway between two houses is narrow, not leaving enough width for external cladding. In this case, a section would need internal insulation.

| TIP!

Get the right people!

Finding skilled installers will be important, as precise work is key for a successful insulation job. They must deal properly with all the external pipes and other gubbins so they don’t leave uninsulated thermal bridges.

With EWI systems you ensure the durability of your building:

- On impact

- To mechanical stresses

- To time

- To weather conditions

- To wind pressure

Which type of EWI should I use?

Expanded polystyrene/ EPS

(Expanded polystyrene/ EPS)

Expanded polystyrene, or EPS, is the most popular and least expensive insulation material used in EWI systems available on the market at the moment. The white EPS we’re all familiar with has been the mainstay of external insulation for years and has a typical thermal conductivity of 0.037 to 0.040 W/mK.

EPS is regarded as easy to work with. It’s lightweight, cuts easily yet is quite robust. It’s also well suited to our climate in that it can get wet during installation without suffering any loss of thermal value. Because it’s so common, you can get it in virtually any thickness you want.

Graphite Extruded Polystyrene insulation

(Graphite Extruded Polystyrene insulation)

More recently EPS is been superseded by grey EPS, which is graphite enhanced and has a superior conductivity value of circa 0.031 W/mK. Effectively what this means is you get the same performance from a thinner profile.

Extruded polystyrene insulation/ XPS

(Extruded polystyrene insulation/ XPS)

Manufactured since the 1940s, the process of extruding foamed polystyrene results in a material with uniformly small, closed cells, which gives the foam superior rigidity, making it highly resistant to compression, and a thermal conductivity of circa 0.34 W/mK. XPS has natural resistance to rain, snow, frost and water vapour, and is an exceptionally stable material, retaining its initial insulation performance and physical integrity in exposed conditions over long durations.

Properly installed, XPS boards have a service life comparable with that of the building or structure. XPS is commonly used for the plinth detail, below DPC in many external insulation systems, because of its unique benefits – but it can be used for a whole wall system.

Rockwool Mineral wool

Another familiar material, mineral wool sits at the lower cost end of the spectrum and has a thermal conductivity in the region of 0.036 W/mK.

It’s got the best fireproof credentials – mineral wool just won’t burn. This is one reason why it’s often specified in social housing and commercial multi-storey buildings, and why it’s used as a firebreak in other projects. It’s regarded as a little harder to work with; it’s more difficult to cut and has that ‘itchy’ factor. It also needs to be kept dry during the installation.

Having said that, if it does get wet, its performance will return once it’s allowed to dry out fully. Mineral wool is fully breathable – meaning that any moisture/water vapor in the structure can pass to the exterior surface unobstructed. That said, as with all insulations, breathability is only maintained if the finish is itself breathable.

Reduce your energy consumption today!

Our Brands